Algorithms, optimization and simulation

The management of material flow and production encompasses the handling of all material flows in logistics and production. The main objective is to make the goods available at the right time, in the right place and in the required quantity. However, this can include many different specific objectives. These can include, for example

- increasing the capacity of the system,

- an increase in flexibility (for example in responding to breakdowns or processing rush orders),

- reducing costs by optimizing processes

- and/or increasing delivery capability and reliability.

The exact optimization goals and control options depend on the area of application and can therefore include additional points.

We are engaged in the development of appropriate algorithms to control all systems in which material moves. Additionally to the planning of orders and material supply in the system, we also analyze existing systems on the basis of operating data. The control system can be used in production; other areas of application include warehouse systems or distribution centers where processes such as incoming goods, order picking or shipping are managed. A suitable management system is also required outside the company, e.g. for transportation.

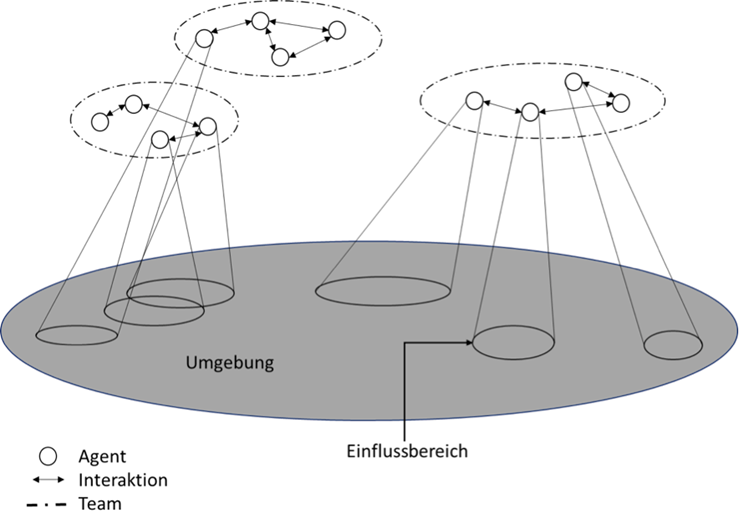

To achieve these goals, we employ various control techniques. Typically, we address these challenges through the application of classic mathematical optimization methods or simulation studies. Nevertheless, more sophisticated approaches exist, including artificial intelligence and decentralized agent-based systems. In such systems, complexity dictates that scheduling occurs not on a central computer but at the specific points where decisions must be executed. This decentralized scheduling is facilitated by independent software agents. Our primary emphasis lies in developing and implementing the requisite control algorithms.