Overview

In 1901 Georg Benoit founded a chair for lift- and transport machines at the Technical University Karlsruhe - worldwide the first of its kind. After two name changes the today's Institute for Material Handling and Logistics had its 100th anniversary in 2001. Besides the institute's name the research priorities have been changed along industrial developments as well. This was done by a tight alliance with the industry and industrial unions. The progressive orientation is the basis for those alliances and for the high acceptance of institute articles and the education of academic procreation for industry and research.

The Beginning

The general interest of the chair founder Benoit has been the construction of cable railways and the research of the wire rope as a eccentric of machine parts. In his 1915 published book "Die Drahtseilfrage" (The wire rope question) he has proven that the (at the time usual but wrong) method for the calculation of bending stress of wires of a wire rope while running over a coil described by his mentor Reuleaux was the right one. This pamphlet against the renowned engineering professor "von Bach" has made Benoit and his chair famous beyond the borders of Germany and created a competency center for the wire rope research in Karlsruhe. His students Wornle, Overlach, Rubin, Dreher and Donandt have discussed questions about wire ropes in their dissertations and doctorates and continued the wire rope research as professors in Karlsruhe and at the Technical Universities in Danzig, Stuttgart and Munich.

|

|

|

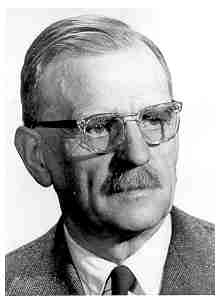

||

| Geh. Hofrat Prof. Dr.-Ing. E. h. Georg Benoit Institute director 1901 - 1936 |

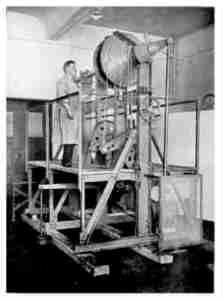

Benoits cable wire test machine | Title of "Die Drahtseilfrage" |

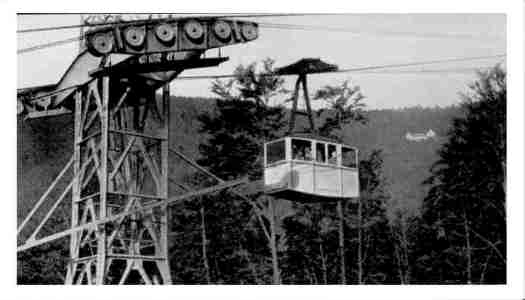

With the intellectual direction of Benoits the first closed loop working cable railway for passanger transportation was built in 1930. This railway on "Schauninsland" near Freiburg was in use for decades and was admitted as a model to the collection of german master pieces of engineering in the German Museum. Earlier drafts for cable railways from Benoit, e.g t the Aiguille du Midi or the Patschekofel near Innsbruck were never built since the time was not ready for his keen projects.

|

| cable railway at Schauinsland 1930 |

In 1936 Hans Overlach became the head of the chair for figuring and transport machines as successor of his teacher, by then secretly designated aulic council Prof. Dr.-Ing. E.h. Georg Benoit. An electromagentic cable testing unit for a nondestructive test of cables for cable railways was built under the directorate of Overlach with the technical expertise at that time and was tested in applied operations. The existing chair workshop was expanded considerably and a big conveyor technique department was plant but never built due to the chaos of war. Prof. H. Overlach had to stop his job in 1945 when the University closed. There was not much left of the altitudinarian plans, the Third Reich was typical for, but Benoit's work he started 44 years ago.

|

| Prof. Dr.-Ing. Hans Overlach Institute director 1936 - 1945 |

Rebuilding

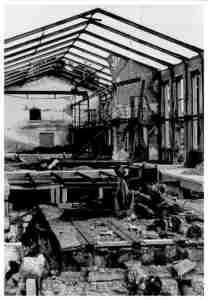

The department was, like many others of the Technical University Karlsruhe, destroyed almost completely by the war. The complete workshop equipment, the model collection, valuable measuring instruments and the extensive library was lost - partly by bombings, partly by depredation.

|

|

|

| Prof. Dr.-Ing. Hermann Donandt Institute director 1947 - 1966 |

War damages at the Institute |

In 1947 Hermann Donandt also a student of Benoit assumed the destroyed chair and the difficult task of rebuilding. The chairs activities were impressed by his connections to the elevator industry, the cooperation in the technical boards and the development of electronic pulleys. Besides activities on gripping devices, traction sheaves and hydraulic cylinders for elevators the tradition of wire rope research with experimental and therotical studies was continued.

Karl Schmidt resolved the stress of bending wire ropes due to secondary tension in his renowed dissertation from 1965 because of the continuation of the chair.

|

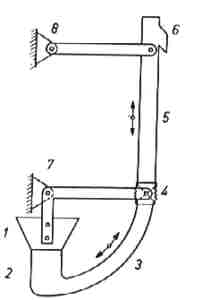

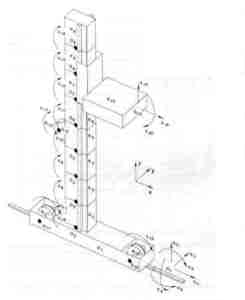

1: feed hopper 2: downpipe 3: bended pipe 4: follower 5: perpendicular conveying 6: discharge port 7: 7 and 8 fixed links |

||

| Perpendicular oscillating conveyor according to H. Donandt | |||

In 1964 the Institute for Conveying Technology moved into a bigger and new building with an experimental hall, a workshop, labs and offices for four scientific officers. With it the provisional arrangement as a result of the war were overcome.

Under the leadership of Donandt questions of bulk goods conveyer technic were work on. The interest for the concept of a new perpendicular oscillating conveyor, as discussed in the dissertations of K. Feyrer and D. Arnold, will remain in the academic cirlces only at that time. In contrast had the collaboration of Prof. Donandt and his assistants on the development of elevators for highest television tower in the world (at that time) in Moscow a great practical relevance. The company Stahl-Aufzugbau (later Thyssen-Aufzüge) in Stuttgart, under the leadership of Donandts past doctoral candidate Karl Schmidt, got in 1965 the contract to build this spectecular elevator, which was in the degree of its innovations equal to the cable railway of Benoits. With its height of more than 500 m the tower is so long that the tip will move one meter away from the sun during solar radiation due to onesided warming and expansion of the towerwalls and will not return to its basic position until night. Substantial amplitudes were also expected by wind stimulation of the tower. The supporting cables would then strike against the walls of the elevator shaft and would grind there with a velocity of 7 m/s. The "Art of engineering" was one of Donandt's favourite activities and he tried to inspire his students for that.

Growth

From 1966 till 1986 Erich Bahke was the director of the institute for conveyor technic. With his experince from his industrial activities in leadership positions of renowed conveyor technic companies he gave new impulses for research fields at the institute. Research of conveyor belts and plate links chains for instance were added to the traditional research field of wire ropes. The drift conveyor technic research field of Prof. Barth was integrated with its personal and areal capacities and was directed by Prof. Dr.-Ing. Manfred Weber in 1967 as independent department. The activities in the section of bulk goods which were started by Donandt were complemented with work on silo technic and through experimental and practical tests on well drilling chisels.

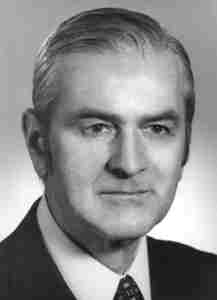

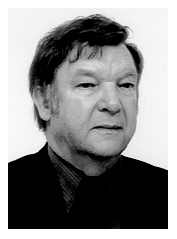

|

| Prof. Dr.-Ing. Dr.-Ing. E. h. Erich Bahke Institute director 1966 - 1986 |

Aside the experimental research of axial reciprocating engine was started. As a result the excellent dissertation of W. Walzer was developed.

In 1975 the department "New transport technologies" was started with own labs and offices. The department dedicated its research power the different forms of person and good transportation. To mention e.g.: Pipe railways, magnetic monorail, cabin taxis and Bahke's favourite the multifunctional material railway, which could transport people, containers and bulk goods on the same railway. The time was not ready for most of the ideas. Only the big electro trolley conveyor was used as a transport devices at the construction of the Itaipu-retaining dam. Bahke published in 1973 his trendsetting ideas in the notable book "Transpotsysteme heute und morgen". The Pipe railway which was experimented upon a lot at the institute had a realisation chance as a material transporter at a pilot project in North Rhine-Westphalia.

|

| Multifunctional material railway from E. Bahke: "Transportsysteme heute und morgen", 1973 |

In the course of the work in the department "New transport technologies" the topics material flow and logistic, which acquire more importance since the seventies, were intensified. The dissertations of F. Thomas, T. Rummert and R. Roth provided among other things contributions on the appliance of the simulation technic.

Bahkes activities shifted to reloading points of transportn networks for railway, trucks, ships and planes and also to the interiors of factories.

The Institue for Conveying Technology of the TH Karlsruhe had developed a new directions of its work. Bahke's predecessors used to research the engineering (constructing) apsects of conveyor technology, which moved to the background in favour of a superior, material flow oriented, logistic view of things. The number of staff member had quadrupled from 1966 till 1986. Further due to Bahke's event management the degree of popularity was raised and the institue can profit by that popularity till now.

Consolidation

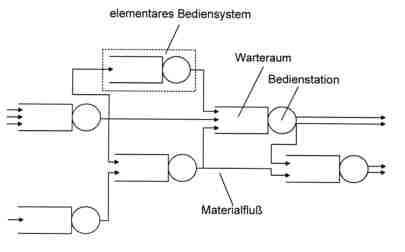

In the summer of 1986 Dieter Arnold began as director of the institute. As one of Donandt's students and Donandt's sudden death he was the first one to finish his dissertation with Prof. Bahke. After that he collected practiacl experinces for 16 years in the construction of conveying machines. After 1986 the institues work was concentrated on flow conveyor technology and three other core areas. The research of the properties of inner and outer corporate logistic systems, which was started under the directorship of Prof. Bahke is continued in the first core area. Main idea is the reproduction of real systems in formal models and the resolution of practical problems in a model. That is how stochastic and nonlinear effects get transparent and their parameter effect can be analysed one by one. The event driven simulation next to the developed and modified operations on the basis of the queuing theory are the basis for analytic methods. Specific research results on the modelling of logistic systems as queuing networks have been performed in this area; the dissertations of R Bryda, K. Furmans, M. Greiling, B. Rall and V Dörrsam and the habilitation of K. Furmans have to be highlighted in that context. Intensive work with considerable results have also been made in the areas of layout design as well as storage- and commissioning systems. The excellent dissertation of K. Alicke has motivated more research in the field of commissioning strategies.

|

| Prof. Dr.-Ing. Dr. h.c. Dieter Arnold Institute director 1986 - 2005 |

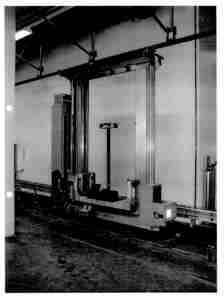

In the second core area Dynamic problems of conveying machines are being analysed. Since 1988 is the most important field in that area the research of rack feeders. Those virtual driveable elevators describe a lot of practical problems and are excellent objects for the teachings of conveyor technology. Almost every aspect of the education of a mechanial engineer is covered: Statics, dynamics, propulsion- and control technology, all important machine elements as well as questions about project management and system integration in big constructions. The research in the area of rack feeders of the institute was only possible in model measures or with computer simulations. Since fall 2000 the institute has an experimental hall with the possibility to experiment on rack feeders in original size. This gives the institute the chance to validate its work, e.g. the interdependency between the oscillation of the tower, the drive control and the commission remedy at the rack feeder. Important research results are the dissertations of M. Schumacher, R. Assmann and M. Dietzel. A new test construction can analyse parameters of catch breaks of rack feeders and can be compared to theoretical results.

|

|

|||

|

Multi-body system of a rack feeder |

Service system network (principle) |

Assembly of a rack feeder in the new

experimental hall

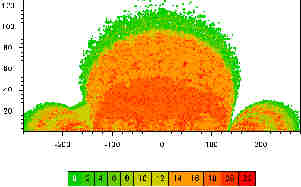

The study of the movement of transport materials is enclosed in the studies of dynamic problems of conveying machines. Application oriented tests, which could not been done in a theoretical enviroment, on heavy duty sorters are done in the new experimental hall. Some of the tests are the delivery, the deposit and the stacking of limp or abnormal formed materials. A third core area of the institutes work was formed in cooperation of the first two, since questions about codification and identification arise while working with automatic conveying and sorting processes. Experimental analysis and the coaction with system controls on numerous identifications systems with optical and electronical readable data storage mediums were done under operational terms. Machine and enviroment specific influences in the indetification process have been resolved in the dissertation of G. Hansen, A Hüser, G. Reuter and P. Fery. The automatic measuring of the communication bandwidth (s. picture) of any commerical identification system is possible with the help of a specific experimental set-ups. The staff of the Institute has been consulted by over 250 companies on projects in the identification technic over the last ten years - some of those projects were financially aided by the state Baden-Württemberg.

|

| Communication bandwith of a RFID system AEG - ID 200 |

The research area of flow conveying - integrated in 1967 - was reorganized and expanded under the leadership of M. Weber. This fourth core area won worldwide recognition, since its involvement in many successfull research and industrial projects. The research used methods and cognitions of Prof. Barth, but developed its own as well. The topics concentrated on two categories.

|

| Prof. Dr.-Ing. Manfred Weber Director flow conveying technic 1967 - 2000 |

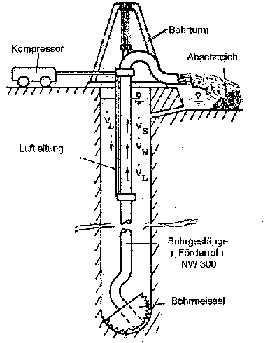

The area of hydraulic solid matter transport including air lifting transport had the main focus of research capacities due to current interest of the industry and due to spectecular projects. The first big research project caused a big experiment with an air elevating drill in the brown coal open pit "Fortuna". This experiment made the calculation basics for water and solid matter transportation from big depth more realistic and safe. The dissertations of J. Rautenberg and M. Y. Dedegil as well as several other publications on that topic from Dedegil and Weber lead to more basic and pratical researches at the request of the DFG, the BMFT and others.

Fundamental research as well as profitability and producibility studies for the pipeline transport of coal and ore were conducted. In coherence the dissertations of E.Gödde, G. Feldle, Kl. Wagner, Kl. Schade, H.-G. Scheurell and B. Zai were developed. In the course of time the focus of the department moved towards rheology; viz. towards high-viscosity and not Netwon solid matter fluid composites in the building industry.

The pneumatic solid matter transport was with its tradition from Barth, which was brought to the institute by Weber, always a field of special interest. The title of Webers habilitation "Schallgeschwindigkeit und kritischer Strömungszustand in Gas-Feststoff-Gemischen" is symbol for that special interest.

The peumatic conveying principle has due to the poor density of the gaseous carrier medium and the compressibility performance limits and is confined to internal dimensions. All the more important were the ambitions in the fundamental research, to enhance the understanding of these complex gaseous/solid-matter streams. In research contracts from the DFG and other institutions the dissertations of F. Rizk, N. Schauki, K.-H. Scholl, W. Stegmaier, D. Werner, G. Szikszay and B. Schade were important contributions to the research field. Stegmaier published as first one the dimensionless regression of comprehensive matter for the important solid matter coeffiction of friction. Weber and Dedegil improved the special multidimensional regression method which was widely adopted by experts. A database with 6.000 measuring datasets were gathered within an AIF-contract. The datasets contained data with matter speicific and matter overall regression formulars.

|

| Air elevating drill at the brown coal open pit "Fortuna" (max. drilling depth 600m, solid matter up to 100t/h) |

The number of research topics was drastically reduced since 1986. The number of employees stayed the same. Therefore the cooperation of the three core areas was enhanced. The knowledge exchange between these areas is intensiv due to expertise intersections.

New topics of the seventies like port and airport technic, axial plunger machines and conveyor belt were dropped, caused by more intensive works elsewhere. The abandonment of the wire rope resarch was difficult since it was pretty much born in Karlsruhe. The Abandonment was made a little bit easier since a former student of Prof. Donandt, Prof. Klaus Feyrer researches on that field in Stuttgart equipped with the most modern equipment.

The Relocation

Since 2000 the Institute for Material Handling and Logistics moved into its own building. The rector of the University Karlsruhe, Prof. Wittig said during the ceremonial handover of the building: The institute evolved since the foundation in 1901 by Prof. Dr.-Ing. E.h. Georg Benoit with its teaching and research duties. The tight cooperation between Prof. Arnold and the industry, which resulted in high third-party funds, needs modern labor and experimental areas.

Presence and perspective

In 2005 Kai Furmans, director of the logistic chair sponsored by the Detlef-Hübner-Stitfung, inherited the directorship of the IFL after the leave of Prof. Arnold. Prof. Furmans intensified the research on areas distribution and production logistics, due to his experiences during his industrial activities. The priorities for distribution logistics are set on the analysis and planning of distributionscenters as well as the coherency between logistics and traffic (productions logistics term: Lean Manufacturing). The results are based on simulations, optimizations of operations research and analytical models.

After the leave of Prof. Arnold in 2005 the research field conveyor technology was newly adjusted. The research fields "Schwingungsverhalten von Fördertechnischen Systemen" and "Sortiersystemen" was retained.

New research areas are the application of new materials for the building of conveying and storage technology machines as well as highly flexible, peripheral driven material flow systems.

Both areas are pretty new and we hope that you will hear a lot of interesting news about them.