MultiSequencer - Development of a compact and flexible m:n sequencing system

- Contact:

- Funding:

- Partner:

- Startdate:

10.06.2019

- Enddate:

30.05.2021

Nowadays, sorting as well as distributing systems are facing various new challenges, e.g. due to highly increasing order volumes within the e-commerce sector. Thus, integrated and automated systems are crucial in terms of in-plant transportation as well as order picking processes. In addition, these systems should guarantee short lead times, scalability as well as high flexibility while at the same time consuming less space and energy. Therefore, modular solutions with decentralized control are state of the art in industrial environments.

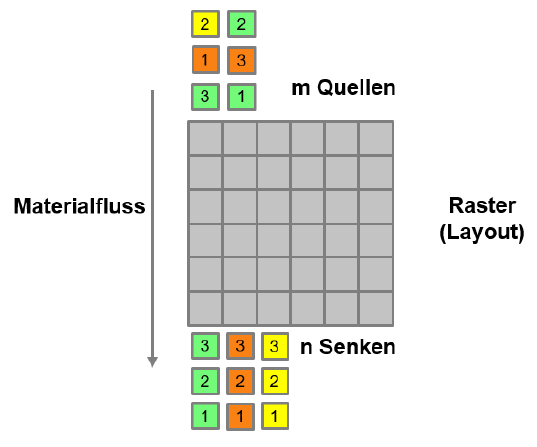

Within the research project, we evolve a modular system, which combines the two tasks of sorting and sequencing. It is based on a rectangular layout made up of single square elements. These are able to transport items in all four directions. By means of an appropriate control algorithm, the modules of the layout have to convey the items which enter the system at one of m sources, in such a way that they arrive at the requested discharge point according to their predefined sequence. This requires both finding a path through the system and buffering of items in case they must not yet reach their destination. Furthermore, the algorithm provides a deadlock handling. All in all, this project aims to refine the sorting function of GridSorter by a sequenced discharge at several sinks.

Applications for the described functionality are for instance:

- High-speed commissioning: Order picking is not processed individually but simultaneously for several orders. Sequencing the items beforehand results in considerably reduced packing times during order picking. Due to the m:n layout, a multisequencer could also serve several picking stations in parallel.

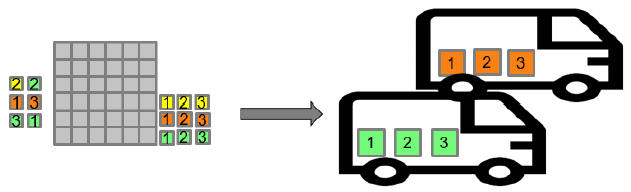

- Milkrun: In-plant means of transport in production areas pick up and deliver bins between several workstations. A multisequencer could prepare the loading sequence of vehicles according to the required sequence at the unloading point. This considerably saves time during unloading since it prevents searching for items manually.

- Logistics service provider: Here, storing parcels sequentially according to the delivery route offers convenience since moving interfering loads is not necessary any more. Sequenced loading is already possible in some applications but this results in very large and technically difficult solutions.

- Storage pre-zone: A multisequencer can serve in both directions within a storage pre-zone. On the one hand, it can be used for sequencing e.g. a returns warehouse in order to raise the workload of the stacker crane and on the other hand for sequencing goods from an automated warehouse for subsequent order picking.

Thus, the goals of the research project are in concrete terms:

- Developing the sequencing algorithm for m:n sequencing in dense grid layouts,

- throughput calculation of sequences in decentralized systems,

- developing a heuristic for efficient layouts and

- deriving practical recommendations for different layouts in order to increase the throughput and lead times of the system.