Productive 4.0

- Contact:

- Project Group:

Logistics Systems

- Funding:

BMBF and EU

- Startdate:

01.05.2017

- Enddate:

30.04.2020

Productive4.0 - ambitious project with a unique main objective

The main objective of Productive4.0 is to achieve significant improvement in digitalising the European industry by means of electronics and ICT. Ultimately, the project aims at suitability for everyday application across all industrial sectors – up to TRL8. It addresses various industrial domains with one single approach, that of digitalisation.

What makes the project unique is the holistic system approach of consistently focusing on the three main pillars: digital production, supply chain networks and product lifecycle management.

This is part of the new concept of introducing seamless automation and network solutions as well as enhancing the transparency of data, their consistence, flexibility and overall efficiency. Currently, such a complex project can only be realised in ECSEL. Representing over 100 relevant partners from 19 EU-member states and associated countries, it is a European project, indeed.

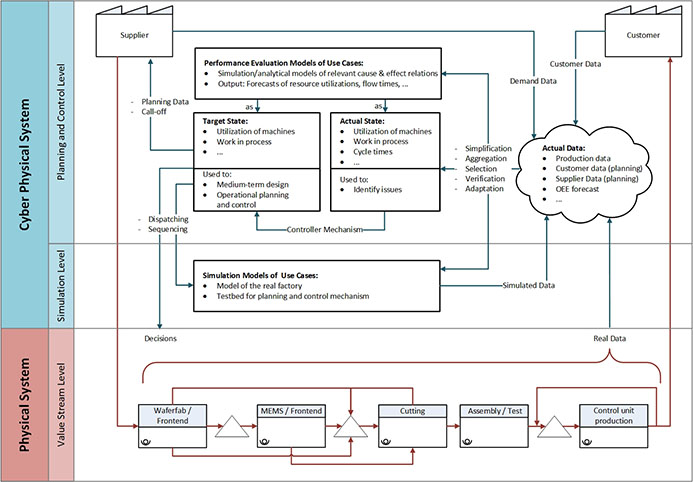

The main objective of the sub-project “analytical models and methods for description, virtualization, performance evaluation and optimization of production systems and supply chain networks“ of the Institute for Material Handling and Logistics (IFL) of the KIT is to develop novel stochastic, quantitative, data-driven evaluation models and decision support approaches for the effective planning and control of production and operations in large production networks that enable improved production management with increased cost efficiency and high levels of service and flexibility in manufacturing and the value creation process in general.

Our plan is to look at manufacturing systems within a cyber physical system (CPS) framework approach that draws on the integrated computational and physical capabilities of today’s production. We will collect and process real data from sales and manufacturing using big data analytics to explore the nature of the demand and production processes. We will especially focus on the randomness of the demand with respect to customer due dates and quantities as well as on the randomness of the production processes caused by stochastic processing times, yield uncertainty and breakdowns of machines. We will use the results from the data analysis to develop analytical and simulation-based stochastic models for evaluating the performance of production networks, and we will further develop optimization models and techniques for the effective design of hierarchical policies for planning and controlling these networks. Special attention will be given to the interface and integration of the different levels of the decision making hierarchy.

In the course of Productive4.0, the Discrete Time Queueing Analyzer (DTQA) has been developed. In this software tool, algorithms from discrete time queueing theory are implemented and can be used via a graphical user interface. The DTQA can be downloaded here.