Description

Due to increased requirements in terms of service quality, response times, flexibility and a high level of service, storage systems, distribution networks and the associated planning and control tasks become more complex.

High inventories conceal imperfections, not only in production, but also in warehousing and picking systems. On fluctuating demands it must be reacted in the shortest possible time. In the case of new and rescheduling, no partial solutions are required but an integrated overall system is required by a synchronized material flow.

Industrial Projects:

- Support in the planning phase:We support companies to varying degrees when it comes to the planning and re-planning of logistics centers. Due to the proximity to research and the regular exchange with intralogistics providers, our employees have knowledge of the state of the art. In our consultancy on the right system, we rely on the experience of numerous projects and can, if desired, also carry out calculations so as to ensure that a suitable and not simply a modern solution is used. In addition to planning and dimensioning, it is also possible to monitor the offer and award phases. We also carry out scenarios for further development and an appropriate interpretation of concepts and concept comparisons.

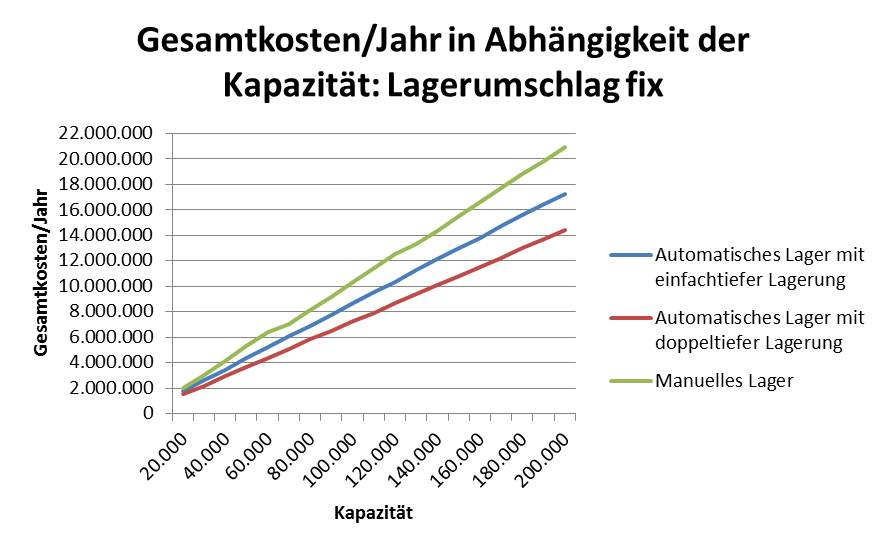

- Analytical decision-making models: On the basis of analytical calculations, an initial assessment of the suitability of storage types can often also be made in connection with other processes of a warehouse such as, for example, the incoming goods and goods exit processes. The analytical approach has the advantage that the effort and thus the costs involved are significantly lower.

- Planning-accompanying material flow simulation: Simulation studies of material flow systems using current simulation software are also part of our portfolio. For example, a throughput analysis of the planned material flow can be carried out and the performance of the conveyor, storage and production systems can be determined.

- Training: Due to the lack of personnel in the logistics and the associated "transitions" there is no basic knowledge about the processes in the distribution center part. Our institute offers you the opportunity to bring your employees to a uniform level with the help of trainings and to provide a basic understanding of the processes. Both techniques and applicable strategies for all processes of farm management, warehousing, warehousing and commissioning, consolidation and packaging, goods issue, value added services, overhead are communicated. We would be happy to focus on your needs or to expand your basic training with modules.